A Data-Driven Pizza Parlor

GOAL

RESULT

PROJECT DURATION

Adrian’s Pizzeria aims to enhance its pizza-making and optimize business operations through data-driven decision-making.

A comprehensive report with insights and recommendations for Adrian’s Pizzeria, facilitating well-informed decisions, cost savings, and process optimization.

The estimated duration of the project is 2 to 3 months, depending on the availability, completeness, and cleanliness of the data.

CASE – OPTIMIZING ADRIAN'S PIZZERIA OPERATIONS

In the bustling world of pizzerias, there’s a hidden gem called “Slice of Poznań.” What sets Adrian’s apart isn’t just its mouthwatering pizzas but its dedication to data-driven decision-making.

The owner Adrian is on a mission to perfect his pizza-making game and optimize his business operations. Let’s dive into how Adrian’s Pizzeria uses data to make every slice count.

Orders: The Heart of the Business

At Slice of Poznań, every order tells a story, and Adrian wants to capture that narrative through data. Here’s what he needs:

- Item name: To know what pizzas are popular.

- Item price: To analyze pricing strategies.

- Quantity: To track demand.

- Customer name: For personalization.

- Delivery address: To ensure popular locations

- Row ID: A unique identifier for orders.

- Order ID: A unique code for each customer’s order.

- Item Name: The name of the ordered pizza.

- Item Category: The pizza’s group, like “Vegetarian.”

- Item Size: The pizza size (e.g., small, medium).

- Item Price: The cost of the pizza.

- Quantity: The number of pizzas ordered.

- Customer First Name: Customer’s first name.

- Customer Last Name: Customer’s last name.

- Delivery Address: The address for pizza delivery.

- Delivery City: The city for delivery.

- Delivery Zip Code: The zip code for delivery location.

Stock Control: Keeping the Pantry Full

Adrian doesn’t want to run out of ingredients during the dinner rush. To prevent this, he needs:

- Ingredients list for each pizza: To know what goes into each pizza.

- Quantity of ingredients per pizza size: Plan inventory based on size.

Imagine making sure you have enough pepperoni and cheese for every pizza size; that level of accuracy is exactly what we’re aiming for.

Staff Control: Making Sure the Team Is Set

Adrian knows that his skilled chefs and delivery staff are key to his success. To manage his team effectively, he wants to:

- Know which staff members are working and when: For efficient staffing.

By understanding labor costs, Adrian can make data-driven decisions on staffing and pricing.

Table Creation

Let’s begin by creating the necessary tables for MySQL usage.

CREATE TABLE `orders` (

`row_id` int NOT NULL ,

`order_id` varchar(10) NOT NULL ,

`created_at` datetime NOT NULL ,

`item_id` varchar(10) NOT NULL ,

`quantity` int NOT NULL ,

`cust_id` int NOT NULL ,

`delivery` boolean NOT NULL ,

`add_id` int NOT NULL ,

PRIMARY KEY (

`row_id`

)

);

CREATE TABLE `customers` (

`cust_id` int NOT NULL ,

`cust_firstname` varchar(50) NOT NULL ,

`cust_lastname` varchar(50) NOT NULL ,

PRIMARY KEY (

`cust_id`

)

);

CREATE TABLE `address` (

`add_id` int NOT NULL ,

`delivery_address1` varchar(200) NOT NULL ,

`delivery_city` varchar(50) NOT NULL ,

`delivery_zipcode` varchar(20) NOT NULL ,

PRIMARY KEY (

`add_id`

)

);

CREATE TABLE `item` (

`item_id` varchar(10) NOT NULL ,

`sku` varchar(20) NOT NULL ,

`item_name` varchar(100) NOT NULL ,

`item_cat` varchar(100) NOT NULL ,

`item_size` varchar(10) NOT NULL ,

`item_price` decimal(10,2) NOT NULL ,

PRIMARY KEY (

`item_id`

)

);

CREATE TABLE `ingredient` (

`ing_id` varchar(10) NOT NULL ,

`ing_name` varchar(200) NOT NULL ,

`ing_weight` int NOT NULL ,

`ing_meas` varchar(20) NOT NULL ,

`ing_price` decimal(5,2) NOT NULL ,

PRIMARY KEY (

`ing_id`

)

);

CREATE TABLE `recipe` (

`row_id` int NOT NULL ,

`recipe_id` varchar(20) NOT NULL ,

`ing_id` varchar(10) NOT NULL ,

`quantity` int NOT NULL ,

PRIMARY KEY (

`row_id`

)

);

CREATE TABLE `inventory` (

`inv_id` int NOT NULL ,

`item_id` varchar(10) NOT NULL ,

`quantity` int NOT NULL ,

PRIMARY KEY (

`inv_id`

)

);

CREATE TABLE `staff` (

`staff_id` varchar(20) NOT NULL ,

`first_name` varchar(50) NOT NULL ,

`last_name` varchar(50) NOT NULL ,

`position` varchar(100) NOT NULL ,

`hourly_rate` decimal(5,2) NOT NULL ,

PRIMARY KEY (

`staff_id`

)

);

CREATE TABLE `shift` (

`shift_id` varchar(20) NOT NULL ,

`day_of_week` varchar(10) NOT NULL ,

`start_time` time NOT NULL ,

`end_time` time NOT NULL ,

PRIMARY KEY (

`shift_id`

)

);

CREATE TABLE `rota` (

`row_id` int NOT NULL ,

`rota_id` varchar(20) NOT NULL ,

`date` datetime NOT NULL ,

`shift_id` varchar(20) NOT NULL ,

`staff_id` varchar(20) NOT NULL ,

PRIMARY KEY (

`row_id`

)

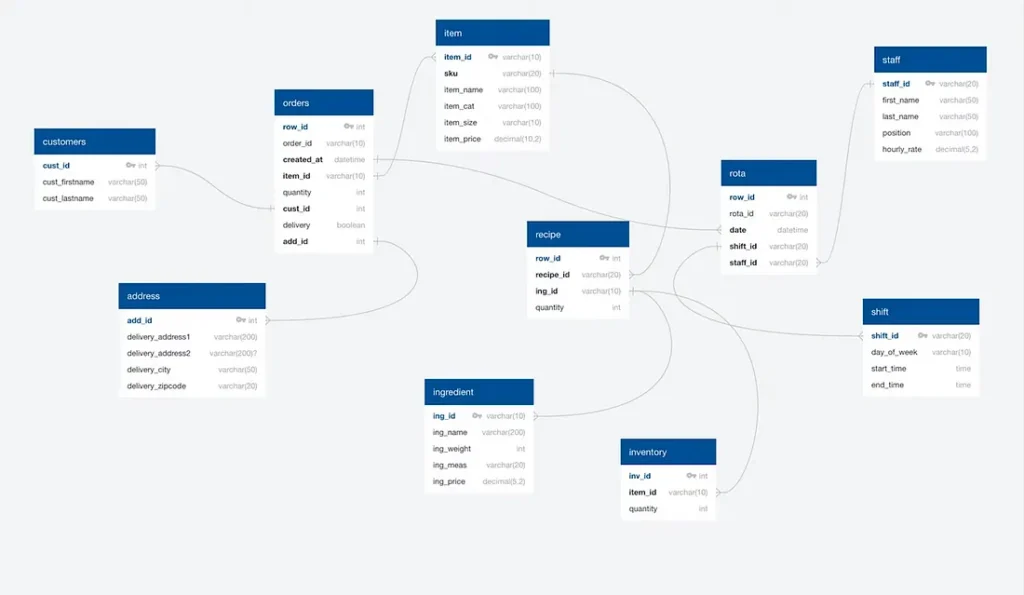

);How tables look after they are created at QuickDatabaseDiagrams.com

Dashboards: Visualizing the Journey with Tableau

Now, let’s talk about the dashboards Adrian uses to make sense of all this data:

Dashboard 1: Order Activity

This dashboard provides a bird’s-eye view of Adrian’s Pizzeria:

- Total orders: Tracking overall demand.

- Total sales: Measuring revenue.

- Total items: Understanding inventory usage.

- Average order value: Analyzing spending habits.

- Sales by category: Identifying popular pizza types.

- Top selling items: Knowing customer favorites.

- Orders by hour: Optimizing staffing.

- Sales by hour: Identifying peak sales times.

- Orders by address: Targeting delivery areas.

Adrian uses this dashboard to fine-tune his operations, from staffing to inventory management.

The SQL code I used to create the first dashboard, which we’ll call “Dashboard 1 — Orders.” This query retrieves data from various tables and joins them to provide insights into order activity. Here’s an explanation of the code:

SELECT

o.order_id,

i.item_price,

o.quantity,

i.item_cat,

i.item_name,

o.created_at,

a.delivery_address1,

a.delivery_city,

a.delivery_zipcode,

o.delivery

FROM

orders o

LEFT JOIN item i ON o.item_id = i.item_id

LEFT JOIN address a ON o.add_id = o.add_idSELECT: Specifies the columns you want to include in the result set.o.order_id: Retrieves the unique order ID.i.item_price: Fetches the item price (pizza price).o.quantity: Gets the quantity of items (number of pizzas) in the order.i.item_cat: Retrieves the item category (e.g., “Vegetarian”).i.item_name: Fetches the item name (pizza name).o.created_at: Retrieves the order creation timestamp.a.delivery_address1: Fetches the delivery address.a.delivery_city: Retrieves the delivery city.a.delivery_zipcode: Retrieves the delivery zip code.o.delivery: Retrieves delivery-related data (possibly a status or method).

This query combines data from the “orders,” “item,” and “address” tables using LEFT JOINs based on the appropriate keys (e.g., order_id, item_id, add_id). It collects essential information about each order, including details about the pizzas, delivery, and customer addresses.

Dashboard 2: Inventory Management

This dashboard provides detailed information on the ingredients used and their respective costs.Total quantity by ingredient: Monitoring ingredient usage.

- Total cost of ingredients: Tracking expenses.

- Calculated cost of each pizza: Ingredient costs + labor costs.

By utilizing this data, Adrian can secure a constant supply of vital ingredients and make informed decisions about pizza pricing to maximize profits.

SQL Code for Inventory Analysis:

SELECT

s1.item_name,

s1.ing_id,

s1.ing_name,

s1.ing_weight,

s1.ing_price,

s1.order_quantity,

s1.recipe_quantity,

s1.order_quantity * s1.recipe_quantity AS ordered_weight,

s1.ing_price / s1.ing_weight AS unit_cost,

(s1.order_quantity * s1.recipe_quantity) * (s1.ing_price / s1.ing_weight) AS ingredient_cost

FROM

(

SELECT

o.item_id,

i.sku,

i.item_name,

r.ing_id,

r.quantity AS recipe_quantity,

SUM(o.quantity) AS order_quantity,

ing.ing_weight,

ing.ing_price,

ing.ing_name

FROM

orders o

LEFT JOIN

item i ON o.item_id = i.item_id

LEFT JOIN

recipe r ON i.sku = r.recipe_id

LEFT JOIN

ingredient ing ON ing.ing_id = r.ing_id

GROUP BY

o.item_id,

i.sku,

i.item_name,

r.ing_id,

r.quantity,

ing.ing_name,

ing.ing_weight,

ing.ing_price

) s1;Creating the Inventory View:

We begin by creating a view called “stock1” to work with the data more effectively:

CREATE VIEW stock1 AS

SELECT

s1.item_name,

s1.ing_id,

s1.ing_name,

s1.ing_weight,

s1.ing_price,

s1.order_quantity,

s1.recipe_quantity,

s1.order_quantity * s1.recipe_quantity AS ordered_weight,

s1.ing_price / s1.ing_weight AS unit_cost,

(s1.order_quantity * s1.recipe_quantity) * (s1.ing_price / s1.ing_weight) AS ingredient_cost

FROM

(

SELECT

o.item_id,

i.sku,

i.item_name,

r.ing_id,

r.quantity AS recipe_quantity,

SUM(o.quantity) AS order_quantity,

ing.ing_weight,

ing.ing_price,

ing.ing_name

FROM

orders o

LEFT JOIN

item i ON o.item_id = i.item_id

LEFT JOIN

recipe r ON i.sku = r.recipe_id

LEFT JOIN

ingredient ing ON ing.ing_id = r.ing_id

GROUP BY

o.item_id,

i.sku,

i.item_name,

r.ing_id,

r.quantity,

ing.ing_name,

ing.ing_weight,

ing.ing_price

) s1;Analyzing Remaining Ingredients:

Lastly, we calculate the total weight of inventory for each ingredient and determine how much is left in stock:

SELECT

s2.ing_name,

s2.ordered_weight,

ing.ing_weight * inv.quantity as total_inv_weight,

(ing.ing_weight * inv.quantity) - s2.ordered_weight as remaining_weight

FROM (SELECT

ing_id,

ing_name,

SUM(ordered_weight) as ordered_weight

FROM

stock1

GROUP BY ing_name, ing_id) s2

LEFT JOIN inventory inv ON inv.item_id = s2.ing_id

LEFT JOIN ingredient ing ON ing.ing_id = s2.ing_id;This analysis allows Adrian’s Pizzeria to make informed decisions about restocking, ingredient costs, pricing, and profitability of each pizza.

Dashboard 3 — Staff Management: Tracking the Workforce

In this segment of Adrian’s Pizzeria’s data journey, we concentrate on managing the staff workforce, utilizing data from three critical tables: rota, staff, and shift.

SQL Code for Staff Analysis:

Step 1: Joining Rota and Staff Tables

We start by joining the “rota” and “staff” tables to create a comprehensive view of staff scheduling:

SELECT

r.date,

s.first_name,

s.last_name,

s.hourly_rate

FROM

rota r

LEFT JOIN

staff s ON r.staff_id = s.staff_id;

Step 2: Including Shift Information

Next, we add shift data to the mix, creating a more detailed picture of staff schedules:

SELECT

r.date,

s.first_name,

s.last_name,

s.hourly_rate,

sh.start_time,

sh.end_time

FROM

rota r

LEFT JOIN

staff s ON r.staff_id = s.staff_id

LEFT JOIN

shift sh ON r.shift_id = sh.shift_id;Step 3: Calculating Staff Costs

Lastly, we calculate the cost of staffing by determining the hours worked and multiplying them by the hourly rate using the TIMEDIFF() function:

SELECT

r.date,

s.first_name,

s.last_name,

s.hourly_rate,

sh.start_time,

sh.end_time,

(

(HOUR(TIMEDIFF(sh.end_time, sh.start_time)) * 60) + MINUTE(TIMEDIFF(sh.end_time, sh.start_time))

) / 60 AS hours_in_shift,

(

(

HOUR(TIMEDIFF(sh.end_time, sh.start_time)) * 60

) + MINUTE(TIMEDIFF(sh.end_time, sh.start_time))

) / 60 * s.hourly_rate AS staff_cost

FROM

rota r

LEFT JOIN

staff s ON r.staff_id = s.staff_id

LEFT JOIN

shift sh ON r.shift_id = sh.shift_id;This data analysis helps Adrian’s Pizzeria efficiently manage its staff schedules and calculate the associated costs, ensuring a well-organized and cost-effective workforce.

You can access my imaginary datasets on my Github and Kaggle accounts for your use and modification.

GitHub

Tableau

Kaggle